NEWS & INSIGHTS

Wetzel New President of Homeyer Precision

Wetzel, 54, assumed the position April 1. He previously served as general manager and has been with Homeyer since 2009.

“It’s a challenge and it’s a great opportunity,” he said. “It’s kind of a dream come true. It’s something that I’ve always aspired to be.

Wetzel said recently he was asked for four words to describe how he’s feeling in his first month at the helm.

“I’m humbled, excited, optimistic and proud,” he said. “I’m humbled for the opportunity to serve this company and its employees. I’m excited for the challenges ahead of us. I’m optimistic for the future with the awesome opportunities we have and the vision we’ve already begun.

“And I’m proud of the accomplishments we’ve made and we’re going to make in the future.”

Herb Homeyer founded Homeyer Precision Manufacturing in 1990 and will stay involved in the company as its CEO.

“Herb has entrusted us the executive leadership team, which consists of Gretchen Homeyer, Justin Homeyer, Walter Blocker and Tim Broughton, to manage the company,” Wetzel said. “He’s still the CEO and owner, but not involved in the day to day operations.”

Wetzel started his career in the industry in 1982 with Supreme Tool and Die Company. At Homeyer, he first worked as a sales manager before being named general manager and now president.

“I think they know me here, they trust me and they believe in what we’re trying to accomplish,” he said.

Wetzel said he has worked as a machinist, quality manager, production scheduler and sales manager. He thinks having served in a variety of different roles will serve him well as Homeyer’s president.

“It gives you a whole new respect,” he said. “It gives you knowledge of all the aspects of all of the business. You absolutely need to have that.”

Despite being the president for less than a month, Wetzel already has goals for the company.

“Our goal is to grow the company and be the best that we can for our customers,” he said. “We want to be among the top shops in the area. We want to be the shop that people chase. We want to be the shop that people look up to. No disrespect to anyone else, but that’s just what we aspire to be.”

Wetzel said another goal is to train the next generation to take over the family business once he’s ready to retire.

“I don’t know if this is necessarily a transition period, but it kind of is,” he said. “It’s a way to bridge the gap between Herb and the next Homeyers to run the business.”

By Joe Barker, Missourian Staff Writer

Credit: http://www.emissourian.com

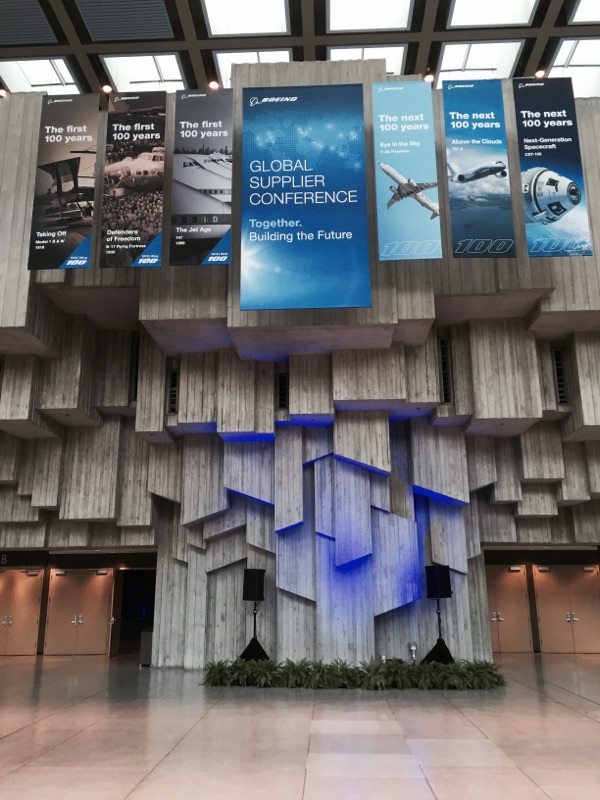

Homeyer Precision Manufacturing receives Silver Boeing Performance Excellence Award

Homeyer Precision Manufacturing is proud to receive the Silver Boeing Performance Excellence Award for 2015.

Homeyer Precision Manufacturing is proud to receive the Silver Boeing Performance Excellence Award for 2015.

Tim Wetzel, General Manager, attended the Boeing Global Supplier Conference where our facility was recognized for this achievement. The Boeing Performance Excellence Award is an annual program to recognize superior performance as measured in BEST.

American Manufacturing Leader Herb Homeyer Introduces IIoT Software to his factory with MERLIN Enterprise Edition

FOR IMMEDIATE RELEASE

American Manufacturing Leader Herb Homeyer Introduces IIoT Software to his factory with MERLIN Enterprise Edition

Marthasville, MO, USA – January 12, 2016 – MEMEX Inc. (TSX-V: OEE) is proud to announce that Homeyer Precision Manufacturing Co. has purchased MERLIN Enterprise Edition for a plant roll-out of Industrial Internet of Things (IIoT) software in Marthasville, MO. The sale includes 23 licenses of MERLIN for Overall Equipment Effectiveness (OEE) and Direct Numerical Control (DNC), plus 9 MERLIN MTConnect hardware adapters for legacy CNC manufacturing machines.

Homeyer Precision Manufacturing is led by its President Herb Homeyer, who is also Chairman of the Board of The National Tooling and Machining Association (NTMA). A passionate business leader, he founded his company in 1990 with a belief in the power of American manufacturing — and a commitment to bring a new level of service to his industry.

“The Industrial Internet of Things, or IIoT, is a powerful trend, and MERLIN makes IIoT real by equipping industrial machines with the necessary interfaces for connecting, collecting, and analyzing manufacturing data in real-time,” said Homeyer. “Our manufacturing team did their homework before choosing MERLIN. One of the things that most impressed us is how no machine is left behind regardless of make or vintage, and MERLIN’s ability to implement quickly on our factory floor without costly integration services or associated time-lags. With this real-time visibility, we look forward to a significant boost in Overall Equipment Effectiveness, or OEE.”

“We are honored to be implementing MEMEX’s IIoT technology in the factory of a visionary manufacturing leader like Herb Homeyer,” said MEMEX CEO David McPhail. “With a correct focus on achieving business value versus simply counting connected devices, IIoT represents no less than the next industrial revolution. The previous three industrial revolutions were mechanization powered by steam engines in the 1800s, mass production powered by electricity and the assembly line in the early 1900s, and automation powered by computers in the late 1900s. Ushering in the fourth industrial revolution, IIoT is powered by the Internet and software applications like MERLIN.”

MEMEX’s flagship software product, MERLIN, is an IIoT shop-floor-to-top-floor communications platform that provides manufacturing analytics in real time. Specifically, MERLIN delivers a 10%-50% average productivity increase, and earns 20%-plus profit improvement based on just a 10% increase in Overall Equipment Effectiveness (OEE). It consistently achieves payback in less than four months with an Internal Rate of Return (IRR) greater than 300%, and connects to any machine, old or new, utilizing native MTConnect, other protocols, or MERLIN hardware adapters for older machines.

About Homeyer Precision Manufacturing Co.

Homeyer Precision Manufacturing serves many different industries from aerospace and defense to oil and gas and energy production. At a time when many high-tech jobs are moving overseas, the company continues to grow in the USA — delivering precision parts for some of the world’s most demanding advanced manufacturing companies for 25 years. Homeyer has achieved this thanks to its ongoing investments in leading edge manufacturing equipment and technology, and its commitment to bringing on the most talented, dedicated, and highly skilled employees for every job.

About MEMEX Inc.

MEMEX is a leading Industrial Internet of Things (IIoT) technology platform provider that delivers manufacturing productivity analytics. MERLIN software provides Overall Equipment Effectiveness (OEE) efficiency metrics in real time, from shop-floor-to-top-floor. Specifically, MERLIN delivers a 10%-50% average productivity increase, and earns 20%-plus profit improvement based on just a 10% increase in Overall Equipment Effectiveness (OEE). It consistently achieves payback in less than four months with an Internal Rate of Return (IRR) greater than 300%, and connects to any machine, old or new, utilizing native MTConnect other protocols or MERLIN hardware adapters for older machines. For more information, please visit: www.MemexOEE.com.

Media Contacts

Homeyer Precision Manufacturing Co. Gretchen Homeyer, Director of Employee, Customer, & Community Relations

Phone: +1 636-433-2244

Email: ghomeyer@homeyertool.com

MEMEX Inc.

David McPhail, CEO

Phone: 519-993-1114

Email: david.mcphail@MemexOEE.com

Nathan Rudyk, VP Marketing

Phone: 905-635-1540 ext. 216

Email: nathan.rudyk@MemexOEE.com

Neither the TSX Venture Exchange nor its Regulation services provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Industry stepping up to challenge of finding, grooming skilled workers

Below is Herb’s letter to the editor that was published in the Boston Globe:

AUGUST 09, 2015

IN RESPONSE to the Aug. 2 article “Is the skills gap real?” (Ideas & Opinion), I offer a resounding yes. As president of a manufacturing company, and chairman of the National Tooling and Machining Association, I know firsthand the difficulty of finding skilled workers. According to a 2015 survey, 84 percent of our member companies have open skilled positions, and 95 percent of those are facing “moderate” or “severe” problems finding employees.

Manufacturers know that this problem cannot be solved by raising wages, though we wish it were that simple. For example, in Massachusetts last year, the average tool and die maker earned more than $50,000, which is consistent with average salaries for other Bay Staters. In some states, wages are considerably higher.

Finally, any notion that industry is blaming American workers for this problem is false. We are not relying on workers to solve it alone. Nearly 70 percent of our members work directly with community and vocational colleges, and another 40 percent recruit from high schools. In addition, many of our members foot the bill for skills training programs.

For us, the biggest challenge is not proving that there is a skills gap — we know it exists. Our challenge is showing a new generation of workers that manufacturing offers great careers and helping them excel in manufacturing today.

Herb Homeyer

Marthasville, Mo.

http://www.bostonglobe.com/opinion/letters/2015/08/08/industry-stepping-challenge-finding-grooming-skilled-workers/dNFuD2DmhENUNla6g09XqL/story.html?event=event25

Homeyer Precision Manufacturing Opens Doors for Manufacturing Day

On October 3rd Homeyer Precision Manufacturing hosted students from Marthasville Elementary, Borgia High School, East Central College, and State Technical College of Missouri in honor of National Manufacturing Day.

We opened our doors to roughly 150 students for a facility tour, a screening of the American Made Movie, and snacks. Manufacturing Day is an important event to Homeyer so we can reach out to the next generation and show them some of amazing opportunities that are available in a career in manufacturing right here in our community. The American Made movie screening gave insight into the importance of manufacturing to the economy and our local communities.

What Do Employers Value Most?

STLCC’s Latest Workforce Research Uncovers New Perceptions on Talent, Cautious Employment Growth

St. Louis Community College’s Workforce Solutions Group presented the fifth annual State of St. Louis Workforce Report, highlighting new employer perceptions on key talent development issues such as the value of online degrees, industry recognized certificates and experienced workers. The report also revealed a slight increase in the number of companies looking to expand employment levels and a corresponding decrease in companies expecting to reduce employment levels.

The findings were released today to more than 400 business and community leaders at the Missouri Botanical Garden as part of a St. Louis Business Journal seminar series. A panel of distinguished corporate executives representing key employing industries also provided a robust discussion of key findings. The seminar was televised live on HEC-TV.

“As we seek to understand trends in employment growth, we also must understand the types of skills, credentials and modalities of instruction that have value in the labor market,” said Roderick Nunn, D.M., vice chancellor for economic development and workforce solutions for St. Louis Community College who also moderated today’s panel discussion. “This year’s research confirms that the economy continues to grow at a steady rate with 38.6 percent of employers expecting to increase employment in the coming year, compared to 33.1 percent a year ago. We also have strong confirmation that industry-recognized certificates and online degrees have significant value among area employers.”

STLCC officials today were joined by executives from AEP River Operations, Edward Jones, Homeyer Precision Manufacturing and SSM Health Care to engage the audience in strategic conversations on the key findings of this annual workforce intelligence report for the region.

In summary, key findings from the fifth annual survey of more than 1,222 employees include:

•As the recession fades into the past and recovery takes hold, employer optimism continues to grow at a slow but steady pace. More employers plan to increase their employment levels and fewer plan to decrease their levels than in 2012. The majority of employers (57 percent) plan to maintain their current levels, reflecting a bias toward caution.

•Economic conditions continue to be cited most often as a barrier to expansion, but the number of employers reporting that as a barrier is down sharply from the previous report. For the first time since the inception of the survey, the shortage of workers with knowledge and skills has replaced government policies as the barrier to expansion most cited after economic conditions.

•While employers continue to recognize substantial shortcomings in their applicant pools, a slack labor market has allowed them to be more selective when hiring. This is reflected in increasing experience and education requirements and in the number of employers reporting that they are hiring only workers who are already trained. These strategies also are necessitated by the need to acquire workers who can adequately function in a growing knowledge economy. Employers both have increased the number of full-time workers they plan to hire and their use of contract employees and temporary agencies. This may reflect different strategies for securing high-skilled versus low-skilled and specialized workers.

•This year’s survey attempted to gauge the premium that employers place on experience and the relative value of industry credentials and online degrees. Given a choice, employers would favor an employee with extensive experience over a recent graduate. They view online degrees and industry credentials as acceptable for entry- and mid-level positions, but favor traditional degrees for advanced positions.

“The key takeaway from today is that there are still a lot of opportunities for partnerships,” said Deborah Walkenhorst, regional vice president for human resources at SSM Health Care-St. Louis. “We seek out those partnership opportunities for the older workforce as well as recent graduates.”

“In terms of hiring, the drought last year ruined crops and weakened the demand for corn. This year we are seeing a bumper crop and expect robust demand. We expect to increase our workforce by 10 to 12 percent,” said Keith Darling, president at AEP River Operations. “The vast majority of our jobs are for unskilled labor and we do on-the-job training. We still have an apprentice program for our skilled labor force because many of our jobs require U.S. Coast Guard certification – regulations demand it. In the river transportation industry, we have found chronic skills gaps in workers because of the licensure requirements, and they must have the requisite experience. Many of our unskilled jobs are filled by younger males because of the physical nature of the work, and we have found some very fine young people. We are really seeing a gap in soft skills such as leadership – because a person has to be in charge of a crew – and in teamwork and collaboration.”

In the manufacturing realm, one local company hires both trade school/community college graduates and experiences workers. There is significant on-the-job training as well as mentoring for skilled positions.

“We prefer to hire individuals with the skills required for the job because that part of our company is so small and we don’t have a good mentoring program yet,” said Herb Homeyer, president and owner of Homeyer Precision Manufacturing. “Individuals with online degrees have not applied for positions with us. What you don’t tend to get with an online program is hands-on or lab work. If you have an online program that couples with hands-on training there is nothing wrong with that. In this industry, hands-on experience is absolutely preferable.

Regarding soft skills, Brian Ashworth, principal in human resources at Edward Jones, said: “It’s not as much about training in critical thinking and problem solving as it is about developing those skills.”

Ashworth has good news for veterans seeking employment. “We have several programs focusing on the military. Close to 1,000 military and ex-military will be hired this year, and veterans possess many transferable skills that meet our needs,” he said.

In addition to Nunn, other presenters were Myrtle Dorsey, chancellor, St. Louis Community College, and Alan Spell, economic and workforce research manager, Missouri Economic Research and Information Center.

For the second straight year, STLCC conducted a survey of recent community college graduates. Nearly 190 STLCC program graduates responded to the survey. In-depth focus groups of interested respondents also were held with graduates to provide the report with more color and context around the students’ experience.

Visit STLCC.edu/STLworkforce to download the full report and/or the four-page summary.

Credit: http://workforcesolutions.stlcc.edu/2013/what-do-employers-value-most/

Homeyer receives Gold Boeing Performance Excellence Award

(Marthasville, MO, February 6, 2013) – Homeyer Tool & Die today announced that it has received a 2012 Boeing Performance Excellence Award. The Boeing Company issues the award annually to recognize suppliers who have achieved superior performance. Homeyer Tool & Die maintained a Gold composite performance rating for each month of the 12-month performance period, from Oct. 1, 2011, to Sept. 30, 2012.

This year, Boeing recognized 594 suppliers who achieved either a Gold or a Silver level Boeing Performance Excellence Award. Homeyer Tool & Die is one of only 153 suppliers to receive the Gold level of recognition.

“This honor is a reward for the excellent team work we have here at Homeyer. Without the dedicated individuals and our commitment to teamwork, none of this would be possible,” said Herb Homeyer, President of Homeyer Precision Manufacturing.

Homeyer Tool & Die supplies special tooling to Boeing for many of their aircraft programs, including F/A-18 and F-15 in St. Louis, V-22 in Philadelphia, and AH-64 Apache in Mesa, AZ.

Homeyer has been delivering precision parts for some of the world’s most demanding industries for more than 20 years. It’s a mark we’ve achieved thanks to our ongoing investments in manufacturing equipment—and our commitment to bringing on the most talented, dedicated, and highly skilled employees for every job. Recently we have moved forward with our vision and rebranded our company and changed our name to Homeyer Precision Manufacturing.

For more information on the Boeing Performance Excellence Award, visit http://www.boeing.com/companyoffices/doingbiz/supplier_portal/bpea.html

Contact: Tim Wetzel, Sales 636.433.2244 twetzel@homeyertool.com

Homeyer Receives William E. Hardman Award for Excellence in Training

Herb Homeyer has been a member of the NTMA since 1996 and he has demonstrated a passion for industry training in many ways over the years.

He has volunteered to serve on several NTMA teams that are focused on leading efforts on workforce development, next generation skilled workforce, and advancements in manufacturing technology, including the NTMA Education Team in which he is currently serving his 5th year – 2 of which he served as team leader; the NTMA Workforce Development Leadership Team in which he is currently serving his 2nd year as the Leadership Team Leader; and he is also currently leading the Military to Manufacturing-Fact Finding Team.

Herb has been instrumental in the formation and advancement of NTMA-U and has been intimately involved in many other NTMA education and training efforts, including the robotics program (NRL), training textbook review and updates, AMPED (formally PJAM), NIMS implementation activities, Foundation grants and scholarships, the National Apprentice Competition, national training awards and the collaborations with groups such as Skills-USA and the AMT/NIMS Student Summit.

The St. Louis Chapter has also been fortunate to have Herb as a steadfast volunteer, holding the offices of the Board of Directors (2005-Present); President (2009-2011), Vice-President (2007–2009), and Trustee, and serving on several chapter committees such as the Workforce Development, Membership, Golf Tournament, and Joint Meeting Committees.

Herb serves on an advisory board for his local high school and college machine tool programs and in the past served on the local Linn State College Advisory Board. He was recognized last year as a longtime WINGS Board Member – an educational foundation for the Washington School District. He is a chamber member of the Marthasville Area Chamber of Commerce and as a company and a family, has supported local charities, schools and churches.

Herb was awarded the NTMA 6S Excellence Award in 2010, in which the goal of this award program is to change the image of the metalworking industry so we can recruit new students into our training programs, retain the employees we have and better market our companies to our customers.

And he received the first annual NTMA Excellence in Manufacturing Technology Award, in which his company was selected based on the technical merit of tools and technologies used to solve a quality issue for the military.

Article credit: NTMA National Staff

KC & St. Louis NTMA Members visit Officials in Washington

The Kansas City and St. Louis Chapters of the NTMA were well represented in Washington DC by a team of members who made the trip to attend the NTMA/PMA “One Voice” legislative conference May 8th and 9th.

Those making the trip were: Dick & Rick Schwind of Continental Tool, Craig Schroer of Unitech Inc, Greg Carr of Deco Tool Supply & Tom Goodpasture of Pride Manufacturing. The group joined with Herb Homeyer of Homeyer Tool & Mike Mittler of Mittler Bro. from the St. Louis Chapter to make visits to both Kansas & Missouri Representatives.

During the-two day event the group visited three US Senators and eight US House Representatives. Issues discussed focused on the serious condition of the trained skilled workers for our industry.

Currently manufacturing suffers with a 600,000 skilled worker shortage nationally with 2.7 million expected to retire in the next 10 years. Taxation and regulation that burdens American manufacturers and makes the US the most expensive place in the world to operate was also discussed. The EPA’s current discussion and consideration of nickel as a hazardous substance was also a hot topic. The team came back feeling that they had a number of good conversations. Manufacturing and the machining industry is being looked to as a solution to create jobs and being welcomed by both sides of the aisle to discuss the possibilities unlike many past years.

Connecting the Technologies

“Imagine it,” says Herb Homeyer, president of Homeyer Tool and Die Company. “The technician loads the feeder with bars and goes home. We have provided him with internet access, and at 8:30 or 9 p.m., he can fire it up and log onto his machine to make sure everything is still good.” As his excitement grows, he says, “We’re not fully there yet, but these are our goals.” Achieving goals is one of his specialties. Read More »