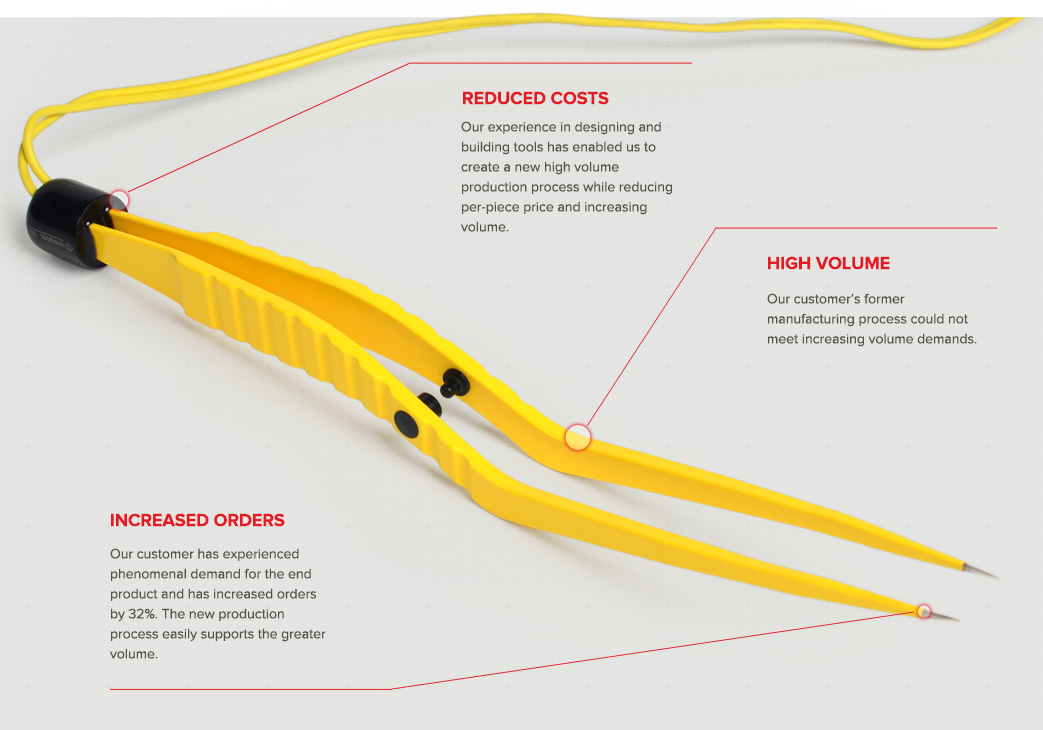

Medical Device Manufacturing

Increasing volume and increasing quality. Our customer’s business had outgrown its existing manufacturing capacity for disposable medical forceps used in brain surgery and other neurological procedures. The customer turned to us to help produce the parts at a higher volume, while maintaining consistent quality and precision.

We designed a new process that could produce the blanks at a faster rate and lower per-piece price. In addition, we produced precision fixtures for holding the parts during machining for repeatability. Our refined process creates a part closer to the near-finish dimension, eliminating several handling steps at the customer’s facility.

Year after year, demand for the part has increased 32%. We continue to study new ways we can improve our manufacturing processes and make finishing the parts easier for our customer.

Click here to request a quote »